Posted this in Tech lounge but decided to add it here as well.

Purpose: Lower IATs, Better Direct Air Flow, Cheap OTRCAI

Reasons:

Didn't have money for Svede OTRCAI at the time.

LS1 maf is damaged / descreened and often fails.

Using lingenfelter CAI without hood liner I am seeing IAT 143ºF while not in motion.

My GTO:

Rather than listing EVERY modification, I'll keep it simple.

LS1 A4

cam, udp, kooks LTs, kook mids, stock 05 catback exhaust, performabuilt stage 2 trans, 3400 stall, hendrix 1 inch shorter radiator

Supplies and Cost:

$35.00 for c6 intake

$38.00 for filter

$80.00 for ls3 maf

$26.00 for adapter harness

$10.00 for cheap solder gun and 4" plastic pipe

$5.00 for coupler with clamps

$10.00 for paint

$15.00 for reflectix

You could do it for cheaper if you go SD tune and cap off the ls3 maf card slot.

Process:

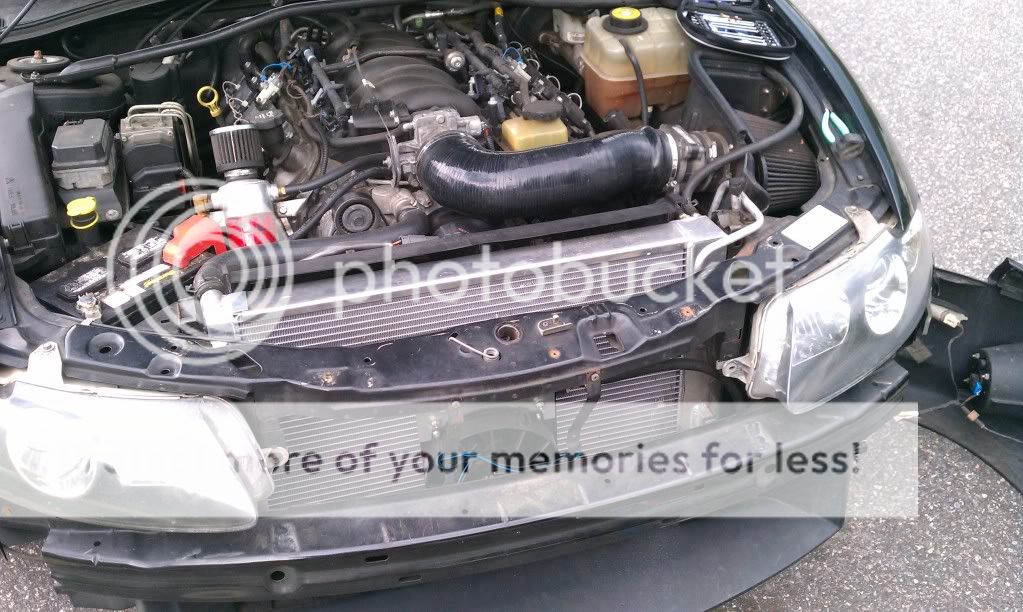

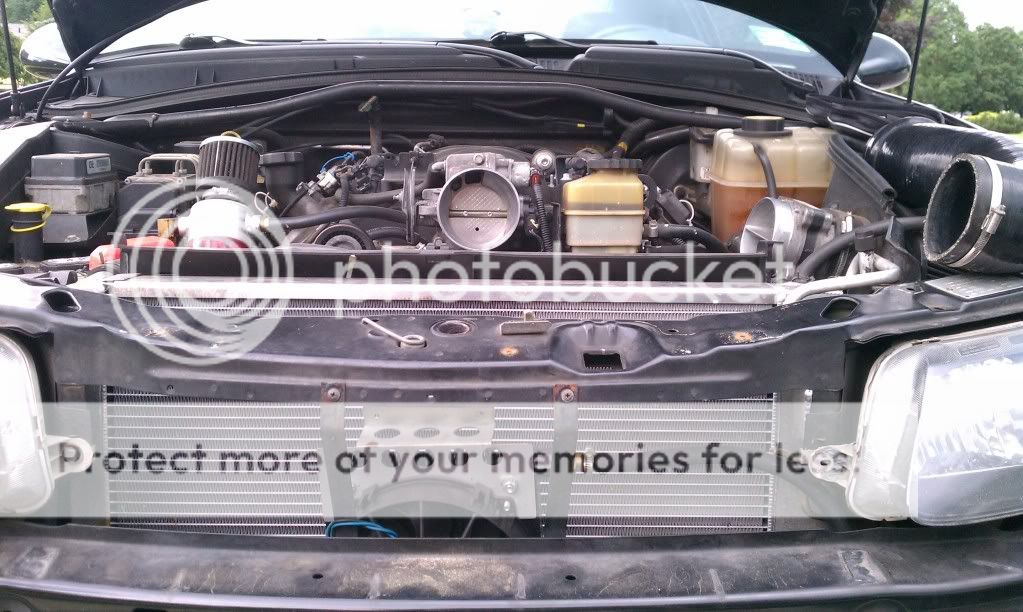

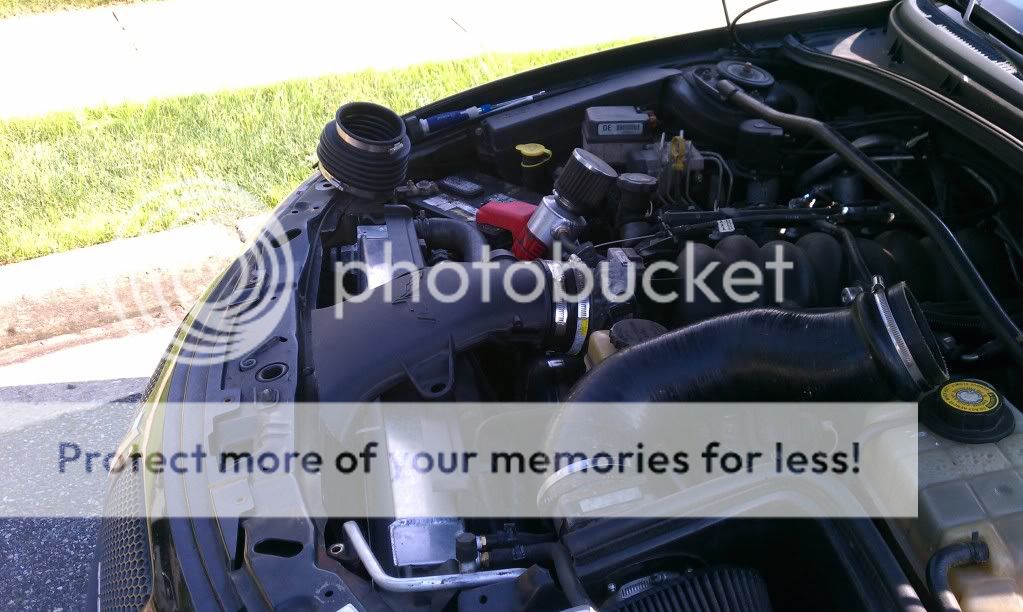

First assess the space I had to work with.

![Image]()

![Image]()

You may notice the lack of an ac condensor, the hard line was cut, not sure when / how it happened but it was, so I took the ac condensor out and I've repaired it and it will be going back in.

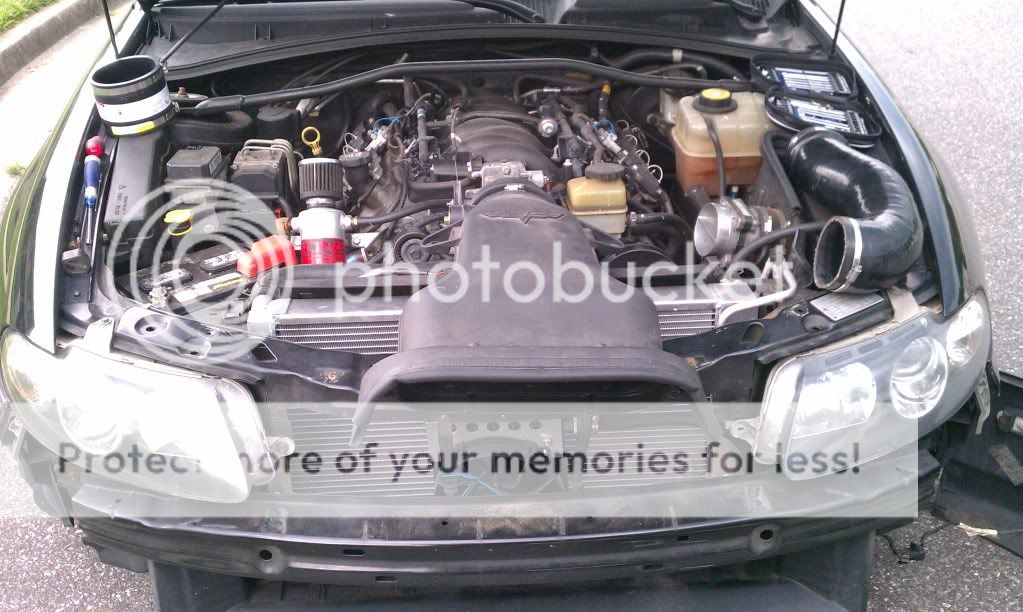

Slap on the c6 intake, cut a hole in the hood and you're good to go! Heh if only. . .

![Image]()

![Image]()

![Image]()

![Image]()

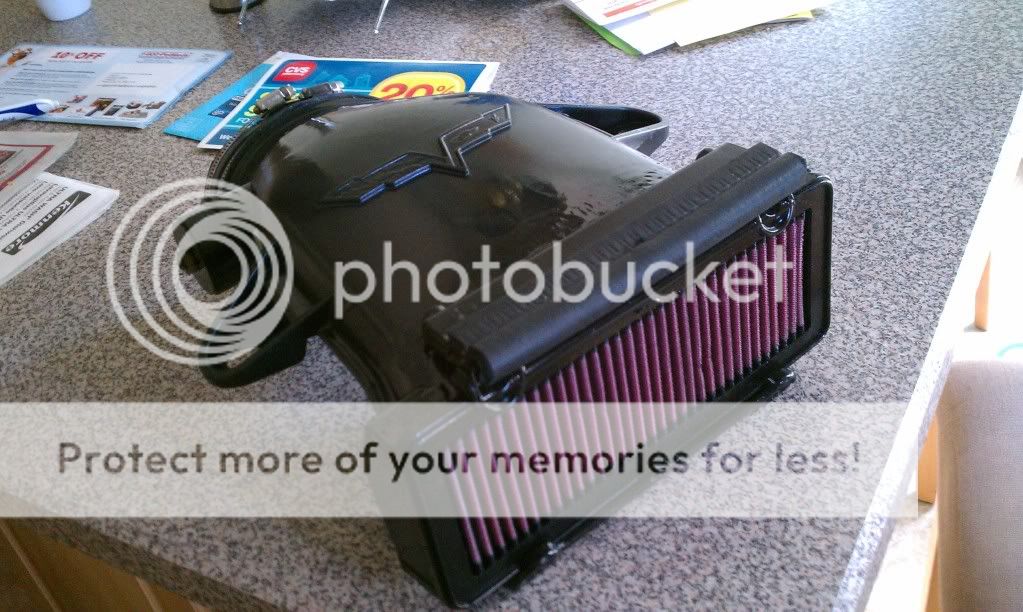

Finally trimmed it to fit. Was hoping with my shorter radiator I could get the air bridge to clear the gap between the hood latch and radiator but unfortunately that didn't work so trimming it down was necessary.

Originally I epoxied all the trimmed pieces of plastic to form an air box for an air filter on the front of the air bridge. Unfortunately this had 2 major flaws. The filter was too small and restricted air flow at high rpms (difference of 13 rwhp) and "plastic epoxy" didn't bond well as I hoped to plastic. You think it would, but it didn't.

![Image]()

![Image]()

Keeping true to the overall goal, I needed a cost effective solution.

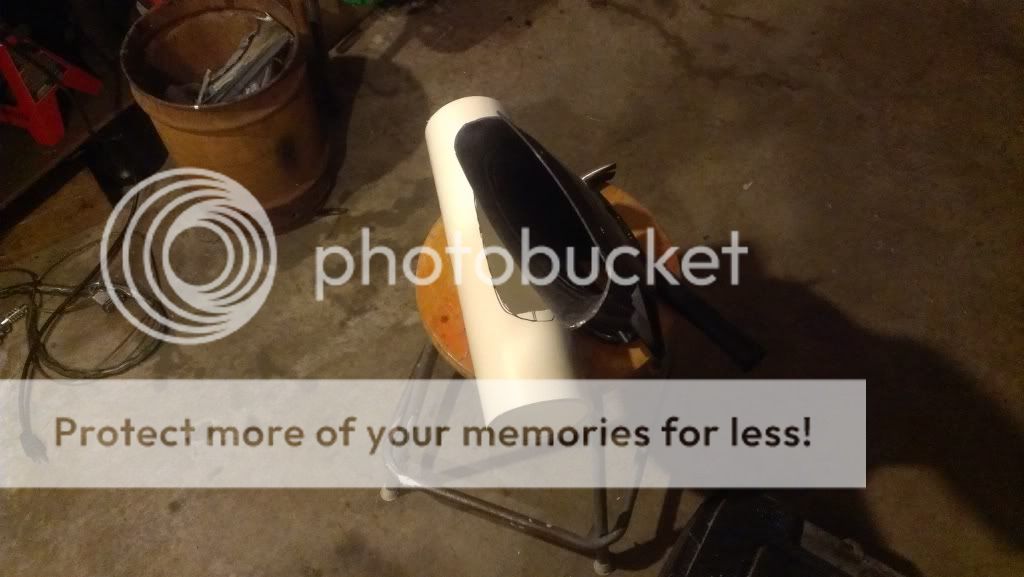

IBM05GTO told me about "plastic welding", turned out to be FAR better than using tubes of epoxy. So the solution turned out to be:

$5.00 4" pipe from home depot and $5.00 soldering iron

![Image]()

Cut a oval-ish hole in the 4" pipe to match the c6 air bridge. Then I removed all the epoxied on pieces I had previously built for holding on the small filter. Then I cut a curve on the opening of the air bridge to match the curve of the pipe. Also I cut the pipe in half with a hacksaw. (To help keep the line straight I drew lines in marker and used my dremel to make a quick groove which I then followed with the hacksaw.) (The dremel I have is the rechargable battery one... I'm impressed it has lasted this long!)

![Image]()

Purpose: Lower IATs, Better Direct Air Flow, Cheap OTRCAI

Reasons:

Didn't have money for Svede OTRCAI at the time.

LS1 maf is damaged / descreened and often fails.

Using lingenfelter CAI without hood liner I am seeing IAT 143ºF while not in motion.

My GTO:

Rather than listing EVERY modification, I'll keep it simple.

LS1 A4

cam, udp, kooks LTs, kook mids, stock 05 catback exhaust, performabuilt stage 2 trans, 3400 stall, hendrix 1 inch shorter radiator

Supplies and Cost:

$35.00 for c6 intake

$38.00 for filter

$80.00 for ls3 maf

$26.00 for adapter harness

$10.00 for cheap solder gun and 4" plastic pipe

$5.00 for coupler with clamps

$10.00 for paint

$15.00 for reflectix

You could do it for cheaper if you go SD tune and cap off the ls3 maf card slot.

Process:

First assess the space I had to work with.

You may notice the lack of an ac condensor, the hard line was cut, not sure when / how it happened but it was, so I took the ac condensor out and I've repaired it and it will be going back in.

Slap on the c6 intake, cut a hole in the hood and you're good to go! Heh if only. . .

Finally trimmed it to fit. Was hoping with my shorter radiator I could get the air bridge to clear the gap between the hood latch and radiator but unfortunately that didn't work so trimming it down was necessary.

Originally I epoxied all the trimmed pieces of plastic to form an air box for an air filter on the front of the air bridge. Unfortunately this had 2 major flaws. The filter was too small and restricted air flow at high rpms (difference of 13 rwhp) and "plastic epoxy" didn't bond well as I hoped to plastic. You think it would, but it didn't.

Keeping true to the overall goal, I needed a cost effective solution.

IBM05GTO told me about "plastic welding", turned out to be FAR better than using tubes of epoxy. So the solution turned out to be:

$5.00 4" pipe from home depot and $5.00 soldering iron

Cut a oval-ish hole in the 4" pipe to match the c6 air bridge. Then I removed all the epoxied on pieces I had previously built for holding on the small filter. Then I cut a curve on the opening of the air bridge to match the curve of the pipe. Also I cut the pipe in half with a hacksaw. (To help keep the line straight I drew lines in marker and used my dremel to make a quick groove which I then followed with the hacksaw.) (The dremel I have is the rechargable battery one... I'm impressed it has lasted this long!)